Metal Seat or Non-Metal Seat

|

|

Size Range 1/2" - 48" (15 - 1200mm) Temperature Range

-62°F to 500°F (-52°C to 260°C)

Pressure Ratings

Max. ASME Class 2500 (420 bar)

Port Type Full, Standard End Type

Flanged, Butt Weld

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Features and Benefits

Trunnion Mounted Ball Valve – A trunnion mounted ball valve has additional mechanical anchoring at the top and bottom on the ball. This special mounting is suitable for larger and higher pressure valves. Moreover, this design allows for reduction in valve torque as the ball is supported in two places. Every ball valve is trunnion mounted. The trunnion mounted stem absorbs the thrust from the line pressure, preventing excess friction between the ball and seats, so even at full rated working pressure operating torque remains low.

Shield TM trunnion mounted ball valves are utilized in some of the most demanding processes in virtually every industry. The extensive range includes soft-seated designs that provide excellent leak-resistance; top entry valves with a one-piece body design that allow in-line maintenance and metal-seated valves that provide superior operation at high temperatures as well as providing abrasion resistance in demanding applications. Welded body designs are ideal for buried service applications to decrease potential leak points and reduce the potential of fugitive emissions from flanges.

Greater efficiency, safety and control enabled by pressure-absorbing bearings, seatsealing action at any rated pressure and anti-static design.

|

|

|  |

|

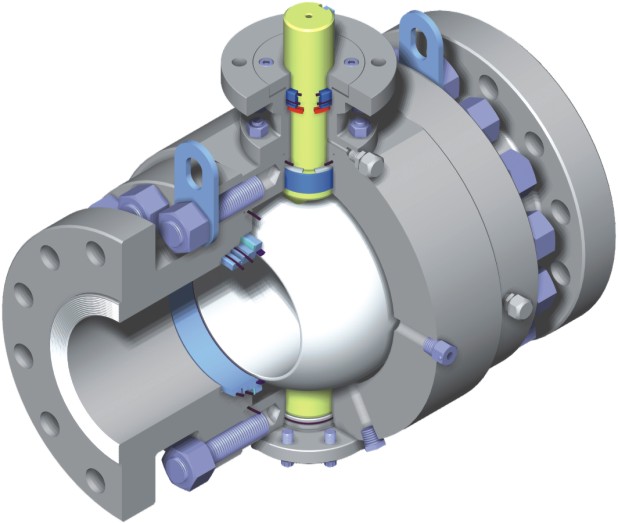

| Side Entry trunnion Ball Valve |

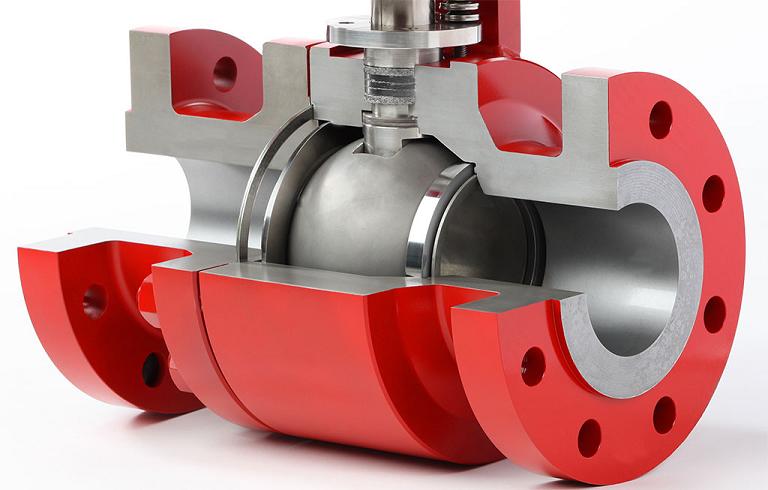

| Top Entry trunnion Ball Valve |

|

Design

ShieldTM trunnion mounted valve series is specially designed to endure the harsh conditions of the oil & gas and petrochemical industries. The robust design tolerates the heavy loads applied to the valve trim that result from of large sizes, high pressures and dynamic temperature cycles. The trunnion valve series is certified to API 6D with a valve wall thickness that is in full compliance with ANSI B16.34.

The complete line is fire safe, designed according to API 607, ISO10497 and API 6FA. Up to class 600 offers a cost-effective solution consisting of a 2-piece & 3- pice solid cast full-port valve. With classes 900, 1500 and 2500, ShieldTM uses a robust 3-piece forged design for body and ends.

|

|

|

|

|

|

|

|

|

|

|

| | Non metal seated Trunnion ball valve |

|

| Metal seated Trunnion ball valve

|

|

|

|

|

Shield TM Ball valves can be used in a variety of applications and markets, such as transmission and storage, gas processing, industrial, and many more. The ball valves provide reliable leak protection which is especially beneficial in gas applications. Ball valves have low pressure drop and can open and close quickly.

A variety of construction materials, trim options and designs make these valves extremely versatile. Ball valves, such as RING-O subsea ball valves, are commonly utilized in subsea applications on manifolds that require long service life at high pressures. Ball valves, also are used in cryogenic applications where compressed gas must be kept at a stable temperature in order to be moved efficiently.

|

|

|

|

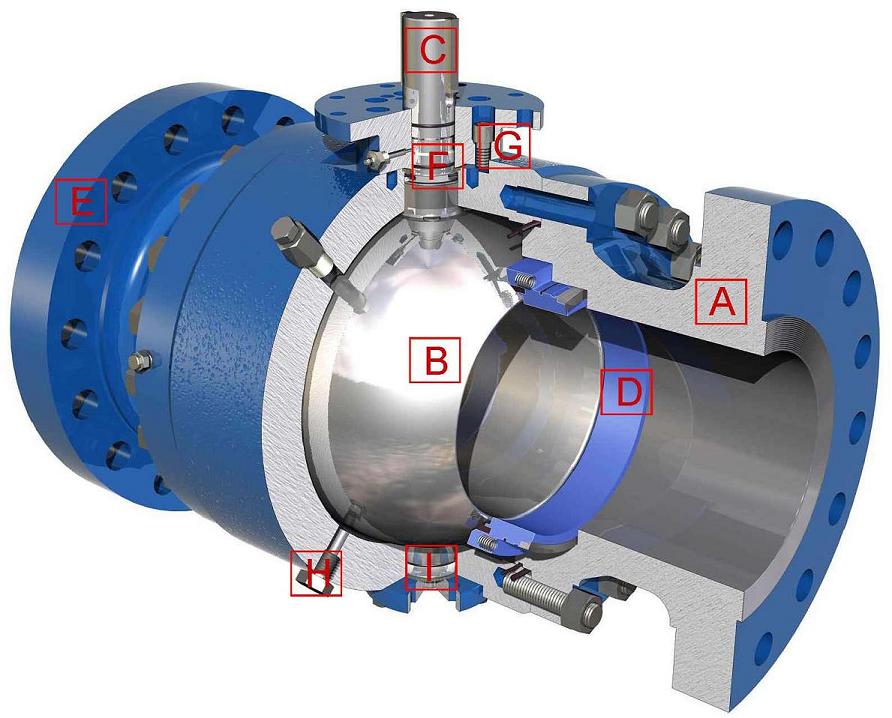

| A BODY: Forged or cast components-bolted body design. | B BALL: precision machined and mirror finished for bubble-tight shutoff and less operating torque.

| C STEM: internal entry and blowout proof for maximum safety. Plant and personnel protected by anti-blowout design that ensures the stem is retained by the stem cover. | D SEAT: ensures a reliable positive shut-off in either flowing direction, bubble-tight sealing with low operating torque. Self relieving or double piston effect seats; Double block bleedEnvironmental compliance assured by zero-emission design | E BONNET: removable bonnet design allows for field replacement of the stem seal without removing the valve from the flow line. | F O- RING: graphite stem seals have been thoroughly fire tested and ensure positive sealing. | G Gland: to ensure the seal performance. | H Injection fitting: used for routine lubrication of the body cavity and injection of emergency sealant. This helps to reduce torque and extend service life. | I Trunion : heavy duty support. |

Options: Valves can be made to order, Metal Seated Designs, Cryogenic Valves, 3-Way Valves, Exotic Alloys and more are available upon request.

|