Replaceable Metal Seat and Seal Ring |  | Size Range 2 - 120" (50 - 3000mm) Temperature Range

-320°F to 842°F (-196°C to 450°C)

Pressure Ratings

Up to ASME Class 900 (160 bar) End Connection Type

Wafer、Lugged、Flanged、Butt Weld

|

|

Triple Offset Butterfly Valve ShieldTMTriple offset butterfly valves are a type of industrial valve that is widely used for regulating the flow of fluids in various applications, which are designed to provide a tight seal with minimal torque, reducing the wear and tear on the valve components; and are designed to have a zero leakage rate and offer superior performance over other types of butterfly valves.

Metal seated butterfly valves are a specific type of Triple offset butterfly valve that offers several advantages over other valve types, including ball valves. Their unique design also provides a high degree of precision and control over the fluid flow.The specifications of a metal seated butterfly valve will depend on the intended application, but they typically include factors such as size, temperature range, pressure rating, and material selection, making them ideal for high-temperature and high-pressure applications. Manufacturers often provide detailed information on their products, including specifications and pricing, to help customers choose the right valve for their needs.

Featurers and Benifits

ShieldTM Triple Offset Metal Seated Butterfly Valves are the premier isolation valves that provide outstanding performance and reliability in a wide range of applications and service conditions. Triple offset butterfly valves designed and manufactured to applicable requirements provide good sealing from vacuum to pressures of 1500 PSI (103 Bar) at temperatures from -425°F (-254°C) to +1500°F (816°C) performance.

The Shield's non-friction metal seal provides zero leakage with minimal torque and is inherently fire safe. Standard seat and seal material is stainless steel, other materials include available Stellite (Stellite) overlay. The elasticity of the seal ring ensures an even seal against the periphery of the seat, providing complete shutoff regardless of flow direction. Triple eccentric butterfly valves offer a rugged metal seal for high temperature and severe applications to ensure bi-directional shutoff over the entire pressure/temperature range. Shield Triple Offset Butterfly Valves allow for independent field replacement of seats and seals. If the service conditions change, the seat and sealing ring parts can be replaced without replacing the entire valve.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| | Integrated seat on Body, |

| S.S Replaceable seat |

| S.S Replaceable resilient seat

| | Seal Ring on the disc |

| Seal ring on the disc

|

| Disc solid seal |

Design

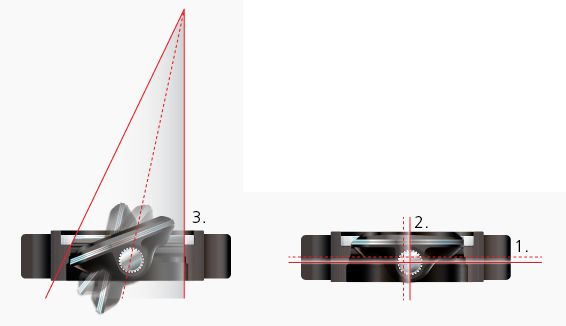

Triple Offset GeometryThe Triple offset valve or triple eccentric valve features a stem that is offset on both the X (1) and Y (2) axis of the butterfly valves center-line. This produces a cam-like motion as the valve operates. The third offset (3) consists of an inclined conical profile machined into the valve sealing surface, allowing rotary engagement and disengagement of the seat and seal ring without interference. This triple offset eliminates all rubbing between the seat and seal ring during valve travel, reducing seat and seal wear and extending cycle life.

Once the seat and seal ring are fully engaged, torque is applied in order to create a bi-directional, zero leak, metal-to-metal seal. For this reason, triple offset valves are often defined as "torque-seated" rather than "position-seated" as in the case of resilient or high-performance products.

Valve Selection When it comes to selecting a metal seated butterfly valve, it is essential to choose a reliable manufacturer that provides high-quality valves that meet industry standards. Several metal seated butterfly valve manufacturers offer a range of products, including high-temperature metal seated butterfly valves with varying specifications, torque ratings, and leakage classes.

Some common applications for metal seated butterfly valves include power plants, chemical processing, and oil and gas refineries. Their ability to handle high temperatures and pressures makes them ideal for these applications.

|

|

|

|

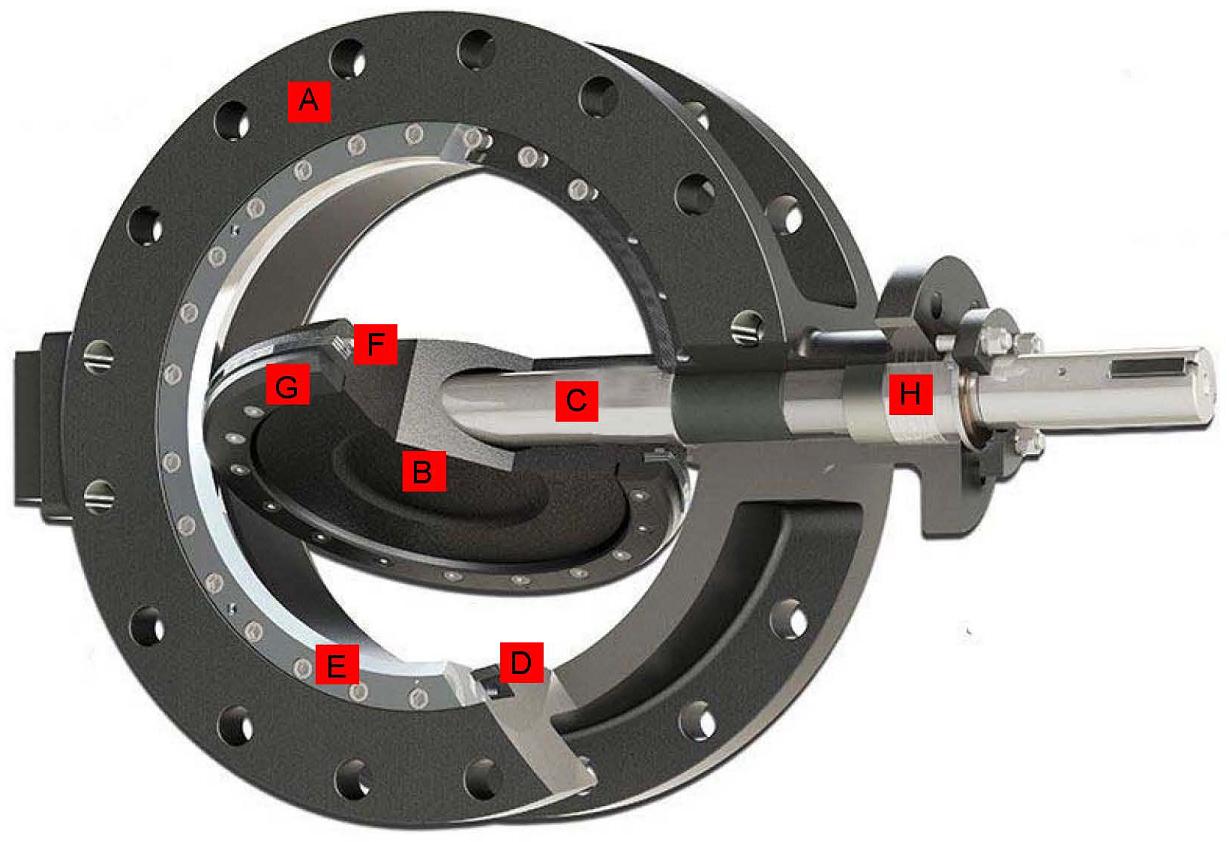

| A Body:Heavy duty body, triple offset construction. | B Disc:The strong and reliable connection allows for axial movement of the stem independent of the disc, to protect the disc/stem connection from temperature fluctuations and pressure effects. | C Stem: Provides positive visual indication of disc/seal ring position after installation. | D Seat:The fully field-replaceable seat extends overall life, minimizes downtime, and and reduces the need for costly off-site repairs or total replacement. | E Seat Retainer: Stainless Steel material to make sure the seat unmoveable. | F Seal Ring:The fully field-replaceable non-rubbing, metal-to-metal sealing system is inherently firesafe and fire-tested, while meeting zero-leakage requirements for many critical applications. | G Seal ring Retainer: Stainless Steel material to make sure the seal ring unmoveable. | H Bushing: Hardened bearings provide maximum stem support. |

|