Metal Seat or Non-Metal Seat

|

| Size Range

1/2" - 12" (15 - 300mm) Temperature Range

-62°F to 500°F (-52°C to 260°C)

Pressure Ratings

Max. ASME Class 1500 (260 bar)

Port Type Full, Standard End Type

Flanged, Butt Weld

|

|

|

|

|

|

|

|

|

|

|

|

|

Features and Benefits

Ball valves can be used in a variety of applications and markets, such as transmission and storage, gas processing, industrial, and many more. The ball valves provide reliable leak protection which is especially beneficial in gas applications. Ball valves have low pressure drop and can open and close quickly. A variety of construction materials, trim options and designs make these valves extremely versatile. Ball valves, such as RING-O subsea ball valves, are commonly utilized in subsea applications on manifolds that require long service life at high pressures. Ball valves, also are used in cryogenic applications where compressed gas must be kept at a stable temperature in order to be moved efficiently.

ShieldTM Floating Ball Valve is a Quarter-turn type of valve, designs fire safe system with anti-static Device. Floating ball valves feature a floating ball design for low torque and increased cycle life. It moves incrementally tighter against the seats as pressure increases. There is injection fitting on body is used for routine lubrication of the body cavity and injection of emergency sealant. This helps to reduce torque and extend service life.

All manually operated valves feature a locking device to prevent unintended movement of ball position.

|

|  |

|

|  |

|

| Side Entry Floating Ball Valve |

|

| Top Entry Floating Ball Valve |

Design

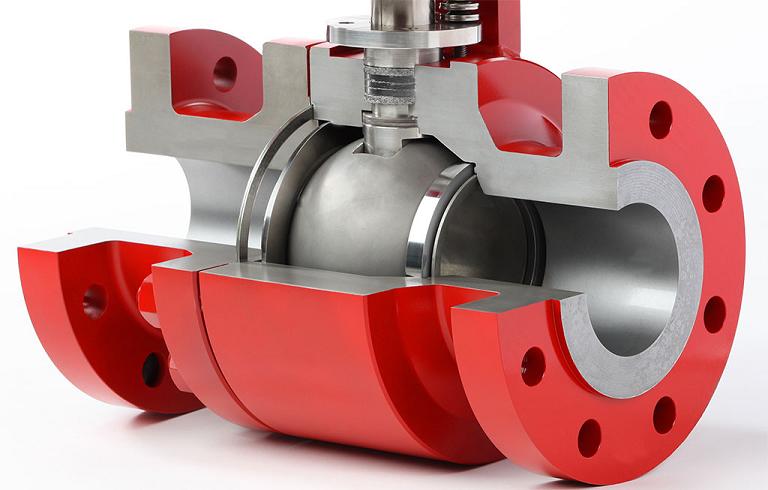

Floating Ball Valve– A floating ball valve is not held in place by a trunnion, and instead is attached only to the stem. This sometimes causes the ball to float slightly downstream. However, when this happens, the ball presses against the seat, creating a positive seal. Bringing together some of the pre-eminent floating ball valve brands, our extensive range of full and reduced bore valves allows you to meet your unique process conditions and helps you achieve optimum results. The floating ball valve portfolio includes a diverse range of standard and customized valves that can be configured to suit most process applications or project packages. There are soft seated designs that provide superior sealing; metal-seated valves that maintain tight shut-off and valves designed to maintain the performance of your processes from elevated temperatures to cryogenic.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

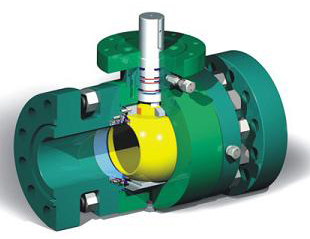

| Non metal seated floating ball valve |

|

| metal seated floating ball valve

|

|

|

|

|

|

Shield TM Floating ball valves feature a floating ball design for low torque and increased cycle life. As standard, larger sized valves feature trunnion-type ball support. These rugged ball valves are ideal for industrial applications.

|

|

|

|

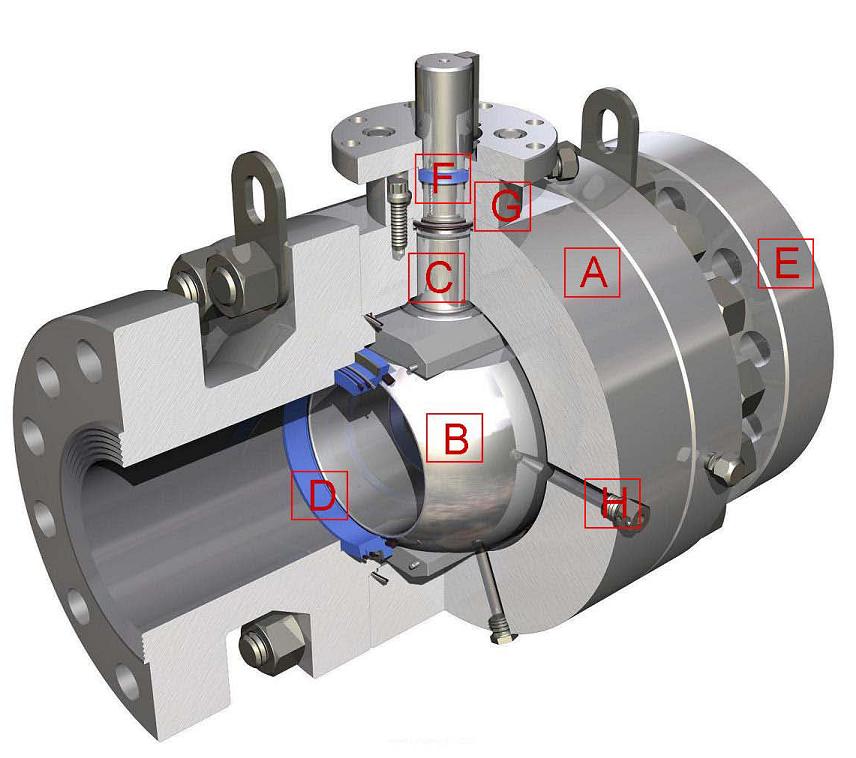

| A BODY: investment cast and solution annealed/normalized for the highest quality and additional strength. | B BALL: precision machined and mirror finished for bubble-tight shutoff and less operating torque.

| C STEM: internal entry and blowout proof for maximum safety | D SEAT: ensures a reliable positive shut-off in either flowing direction, bubble-tight sealing with low operating torque. | E BONNET: removable bonnet design allows for field replacement of the stem seal without removing the valve from the flow line. | F O- RING: graphite stem seals have been thoroughly fire tested and ensure positive sealing. | G Gland: to ensure the seal performance. | H Injection fitting: used for routine lubrication of the body cavity and injection of emergency sealant. This helps to reduce torque and extend service life.

|

|