| Metal or Non-metal Seated |

|

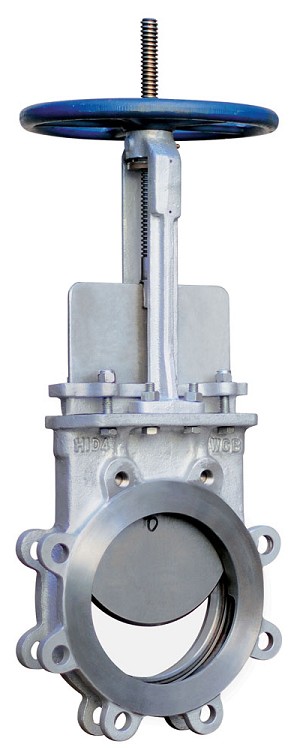

Size Range 2" - 48" (50 - 1200mm) Temperature Range -4°F to 266°F (-10°C to 130°C) Rubber Seat -4°F to 446°F (-10°C to 230°C) Metal Seat Pressure Ratings Max. ASME Class 150 End Type Flanged, Lugged, Wafer Shuttoff ratings Bidirectional and unidirectional Bubble-tight

| |

|

Design

ShieldTM knife gate valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with handwheel, or can be automated with pneumatic cylinder actuator for remote operation. The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles, so the knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making, and Chemical Processing. Soft seated knife gate valves are bi-directional with zero leakage to 10 bar/150 psi in the preferred direction and limited tightness in the non-preferred direction at low pressure. Custom port shapes including V-port, triangle port, and hexagon port are available.

Excellent seat tightness and prolonged life cycle Maintenance to change the seats is easy and fast Superior abrasion and corrosion resistance Strong cutting force for pulp media Clogging or material build-up reduced Reduced torque and easy operation

|

|

|

|

|  | | Rubber seated

|

|

|

|

| Metal seated |

Features and Benefits

ShieldTM Knife Gate Valves are the perfect compliment to our broad range of slurry handling products. All Shield's Knife Gate Valves are designed and engineered to a higher standard, to provide the best performance possible. Standard features such as precision-machines gates, heavy-duty top works and cast-iron bodies up to 24" make the valves rugged and dependable. Other features such as replaceable wear seats, simplified packing replacement or solid stainless steel linings make the valves affordable and easy to maintain.

|

|

|

|

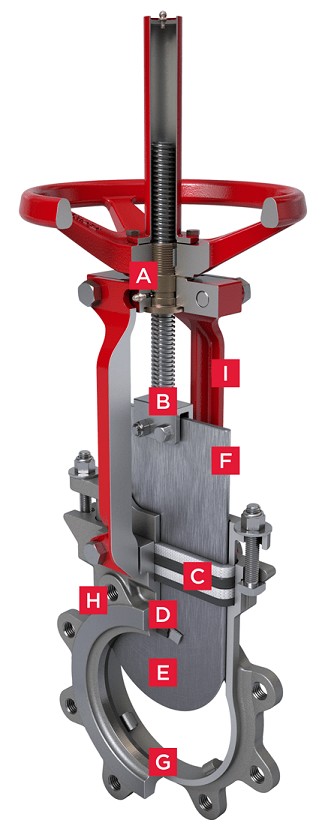

| A. Topworks Topworks designed for easy, quick conversion between manual and pneumatic actuation. Manual valves include a lubricant injection port for continuous, smooth operation with minimal maintenance. | B. Clevis Clevis design and horizontal bolting stabilizes gate ensuring proper alignment.

| C. Packing Standard energized quad seal packing for enhanced gland sealing.

| D. Seat Standard integral metal seat and optional replaceable zero leakage resilient seats. | E. Gate Gate design ensures consistent alignment throughout the length of the stroke. | F. Gate Rounded gate design enables longer packing life and increases valve durability. | G. Body Unique body design with no dead pockets enables self-draining of valve. | H. Mounting Lugged body suitable for all mounting orientations including dead-end service. | I. Yoke Cast Yoke superstructure ensures robustness in valve design for different operators/orientation.

|

|