| Sleeved, Lined or Metal Seated |

|

Size Range

2" - 24" (50 - 600mm) Temperature Range

-50.8°F to 232°F (-46°C to 232°C)

Pressure Ratings

Max. ASME Class 2500 Port Type Full port, Standard port End Type

Flanged, Butt Welded,Thread

| |

|

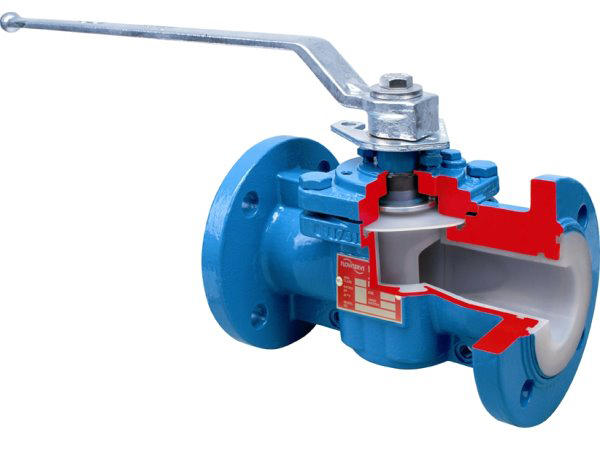

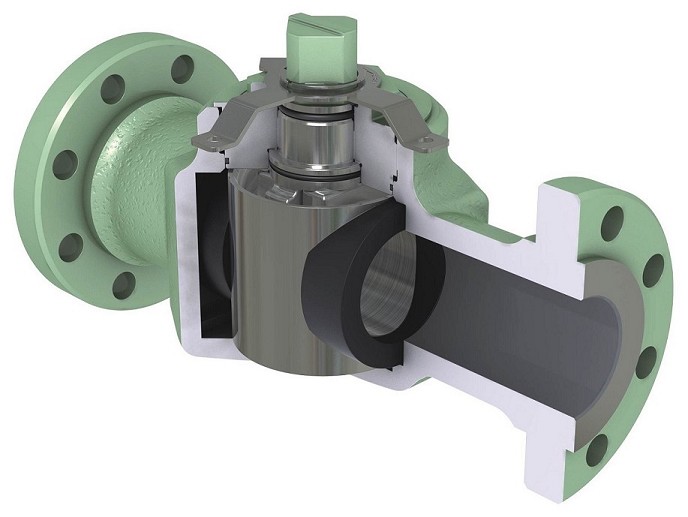

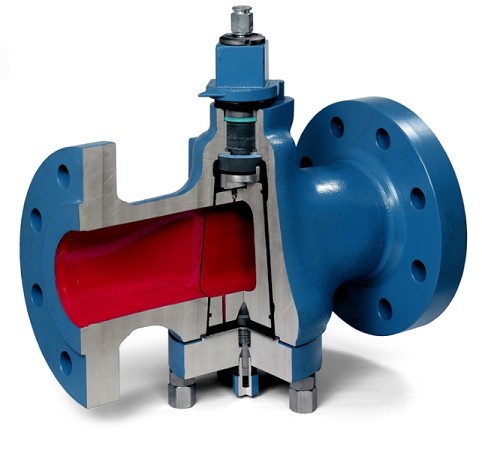

Sleeved & Lined Plug Valve

ShieldTM The sleeve lined or full lined plug valve, is a type of non-lubricated plug valve, interior protects against difficult chemical conditions and offers no cavities for product accumulation. The sleeve or liner to plug contact provides a wiping action which is good for slurry handling. Fully-lined, quarter turn non-lubricated plug valve ideally suited for Chemical Service and corrosive application.

Sleeve is inserted and encaged inside the body. Tapered plug is inserted onto the sleeve. The sleeve is acting as a soft seat. And completely surrounds plug creating areal sealing surfaces. Also not permitting any dead space in the flow path. Plug is rotating 90 degree. When it is aligned with the body port, flow is open. When the plug is rotated so that plug port is perpendicular to the body port the flow is blocked.

Non-lubricated plug valves are usually used for lower pressure lines, and their valve seats tend to deteriorate quicker from the wear and tear of dust, dirt and other debris, compared to those on the lubricated plug valves.

|

|

|

|

|

|

|

|

|

|

| Lined Plug Valve

|

|

|

|

| Sleeved Plug Valve |

|

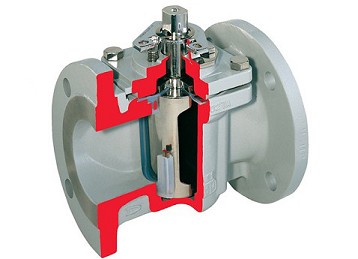

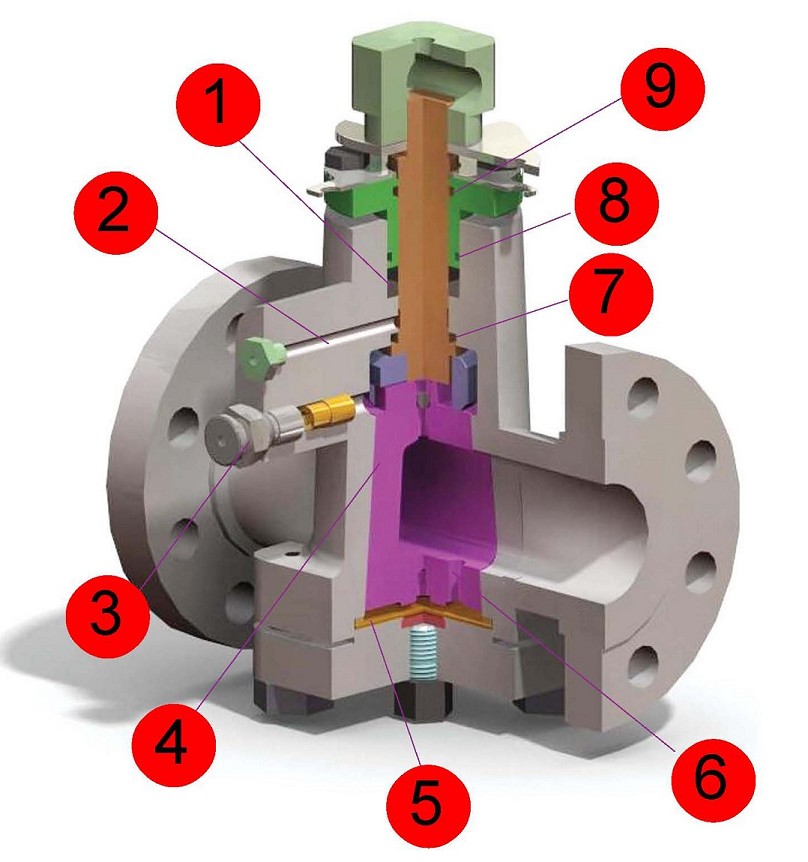

Metal Seated Plug Valve

ShieldTM Metal Seated Plug Valve describes the body and plug contacts directly metal-to-metal. To avoid damage on the sealing surfaces, during opening and closing, the plug is lifted first, and rotated 90 degrees, and then, set to its desired position. The whole opening and closing operation is achieved by one action assuring full proof operation using specially designed and patented operating mechanism.

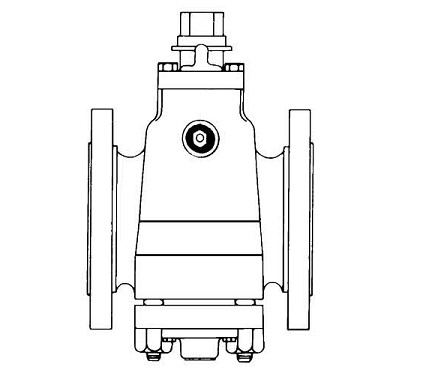

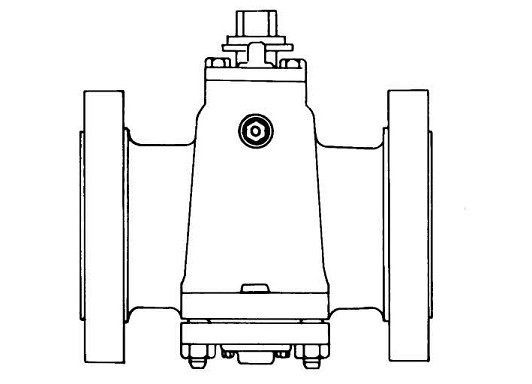

Plug valves are available in a wide range of variants described in the valve patterns, which are defined as Short pattern, regular pattern, and Venturi pattern respectively. The different variants refer to face to face dimension, plug port and shape.

|

|

|

|

|

|

|

|  | | Short pattern |

|

|

| Regular Pattern |

|

|

| Venturi Pattern

|

Metal Seated Plug valves are available in a wide range of variants described in the valve structure, which are defined as standard style and pressure balance inverted lubricated style.

|

|

|

|

|

|

|

|

|

| Standard Style Plug Valve |

|

|

|

| Pressure Balance Inverted Lubricated |

Pressure is balanced by two holes in the plug which connects the plug port with the lower and upper cavities. The hole in the upper end is provided with a check valve so the pressure is always equal to the large end cavity and it is always equal to or greater than the line pressure in the small end cavity.

Pressure balanced plug valves are used where pulsating or static high pressures are present. The benefit a dynamic pressure balanced inverted plug gives is that it ensures equalized pressure between the plug and upper and lower body chambers.

Lubricated Plug Valve delivers the high level of performance you have come to expect with Homestead. Principle applications include natural gas, propane gas, digester gas, liquid asphalt, HVAC balancing, ore slurries, and various other industrial services. Lubricated Plug Valves deliver cost effective quick opening and closing with a tight, leak-proof closure.

|

|

|

|

| 1. GRIPHITE PACKINGS | 2. STEM SEALING COMPOUND INJECTOR TO RENEW SEALING TO ATMOSPHERE

| 3. PLUG SEALANT INJECTOR TO RENEW SEALING TO DOWNSTREAM

| 4. PLUG WITH METAL-TO-METAL SEATING | 5. GRAPHITE PACKING RINGS GIVE NORMAL SEALING AND FIRESEALING | 6. PRESSURE BALANCE HOLES

| 7. THRUST WASHER | | 8. WEATHERSEAL |

|

| 9. BLOWOUT PROOF STEM |

|