| Metal Seated |

| Size Range

2" - 12" (50 - 300mm) Temperature Range

-321°F to 1100°F (-196°C to 593°C)

Pressure Ratings

Max. ASME Class 900 Port Type Full port, Standard port End Type

Flanged, Butt Welded

| |

|

Design

ShieldTM Lift-check valve is a check valve in which the disc, sometimes called a lift, can be lifted up off its seat by higher pressure of inlet or upstream fluid to allow flow to the outlet or downstream side. A guide keeps motion of the disc on a vertical line, so the valve can later reseat properly. When the pressure is no longer higher, gravity or higher downstream pressure will cause the disc to lower onto its seat, shutting the valve to stop reverse flow. Lift check valves are two ways of referring to standard lift check valves. These valves utilize a piston-shaped plug rather than a cone, the high-performance designs of cast steel check valves are used to prevent backflow by reacting to the line fluid in your petrochemical, gas or oil system.

|

|

|

|

|

|

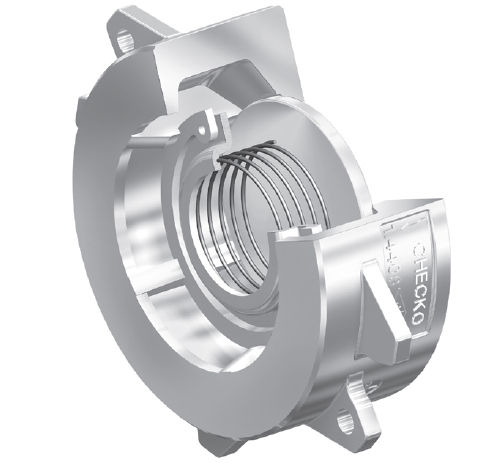

| | Plate Lift Check Valve

|

|

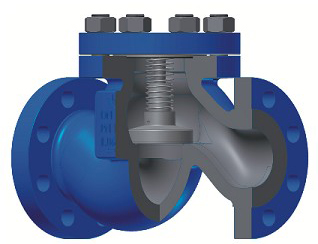

| EN Z type Lift Check Valve |

|

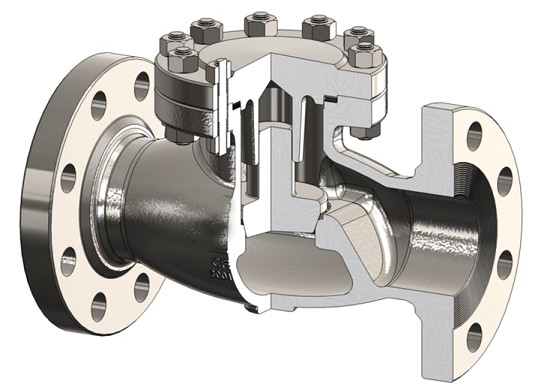

| API T type Lift Check Valve |

Features and Benefits

ShieldTM A lift check valve is commonly used in piping systems in which globe valves are being used as a flow control valve. They have similar seating arrangements as globe valves. Flow to lift check valves must always enter below the seat. As the flow enters, the disk or ball is raised within guides from the seat by the pressure of the upward flow. When the flow stops or reverses, the disk or ball is forced onto the seat of the valve by both the back-flow and gravity.

Applications The lift check valve is a valve which prevents the suction line from running empty, e. g. after the pump has been stopped. Priming the pump prior to a re-start is therefore no longer necessary. They are recommended for use with steam, air, gas, water, and on vapor lines with high flow velocities. Spring-loaded lift check valves can be installed in the piping in almost any mounting position. Compared with swing check valves, their head losses are higher as the deflection of the flow is much more significant.

100% Flow area Energy efficient Fusion Bonded Epoxy - interior and exterior Full Domed Access Cover with Vent Port Side or Bottom Mounted Oil Cushions available Closure Options: Lever & Weight, Air Cushion, Lever & Spring Manufactured under a certified ISO 9001 quality system

|

|

|

|

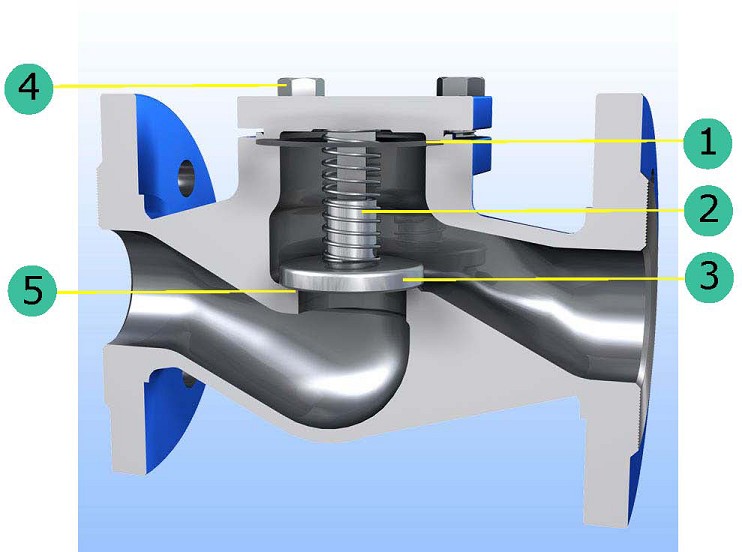

| 1. Flexible graphite gasket for Class 150 valves, spiral wound gasket for Class 300 & 600 valves, and ring joint for Class 900 & above valves or as an option for the Class 600 valves on customer request. | 2. A hinge and hinge pin provided and mounted so as to permit full movement of the disc.

| 3. Standard lift disc type, used in horizontal position for liquid service application or used in vertical position where liquid flow from bottom to top.

| 4. The cover bolting is manufactured of alloy steel in accordance with the requirements of the applicable specifications. | 5. Standard renewable seal welded seat with stellite 6 while optional screwed-in seat.

|

|