Replaceable Seat |  |

Size Range 2 - 60" (50 - 1500mm)

Temperature Range -62°F to 500°F (-52°C to 260°C) Pressure Range ASME Class 300 (50BAR)

End type Wafer, lugged, flanged

|

|

High Performance Butterfly Valve

Shield TM''s High Performance Butterfly Valve is a true marvel of engineering, designed to deliver exceptional performance and reliability in the most demanding industrial applications. As one of the leading high performance butterfly valve manufacturers, we pride ourselves on delivering the highest quality products at competitive prices.

Featuring a Double Offset design, our High Performance Butterfly Valve is the perfect choice for applications that demand precise control, high flow rates, and minimal pressure drop. With its superior performance and durability, this valve has become the go-to choice for industries ranging from chemical processing and power generation to water treatment and more.

Shield's High Performance Butterfly Valve is available in a range of sizes and specifications, making it easy to find the perfect fit for your specific needs. Choose from our wide range of materials, including stainless steel, carbon steel, and high-performance alloys, to ensure that your valve will withstand even the toughest conditions.

With its superior performance and reliability, our High Performance Butterfly Valve offers a range of advantages over traditional ball valves, including lower cost, lower torque requirements, and reduced maintenance requirements. Plus, with its compact design and easy installation, our valve is the perfect choice for space-limited applications.

In addition to its high performance capabilities, our Double Offset Butterfly Valve also boasts a range of advantages over triple offset designs, including lower cost, easier maintenance, and higher Cv ratings.

So if you're looking for a high-performance butterfly valve that will deliver reliable performance and exceptional value, look no further than our High Performance Butterfly Valve. With its superior performance and durability, our valve is the perfect choice for a wide range of industrial applications.

Features and Benefits

Shield TM high performance butterfly valve innovative Double Offset Stem and Disc Design offers rugged reliability and extremely easy maintenance in the field. Independent and internal tests prove superior service life capability, with zero leakage shutoff through over 100,000 cycles. The seat of high performance butterfly valve is self–adjusting for wear and temperature changes. The option of seat includes PTFE, PPL, PEEK Soft Seats and Flexible Metal Seats to suit variety of fluids and applications.

Shield's high performance butterfly valve vailable with proven bi-directional fire safe seats for reliable control of flammable and hazardous fluids in petroleum, petrochemical, chemical and other high-risk applications.The fire safe design combines superior performance, extended service life and compliance with the most demanding worldwide fire-test standards – before, during and after a fire!

Design

ShieldTM high performance Butterfly Valve's full-faced retainer is bolted to the body, locking the seat in the correct position. The seat is secured even without the mating flange.

The closely confined and well supported seat is energized by the disc and line pressure. The higher the pressure, the tighter the seal. In low pressure and vacuum applications, the energized seat offers superior sealing and longer service life than many other designs. Line media is sealed to zero-leakage in both directions.

Seat replacement is extremely easy. Just remove the seat retainer, rotate the disc into the closed position and place a new seat assembly in the machined recess of the body. This simple procedure will not disturb the disc or stem.

|

|

|

|

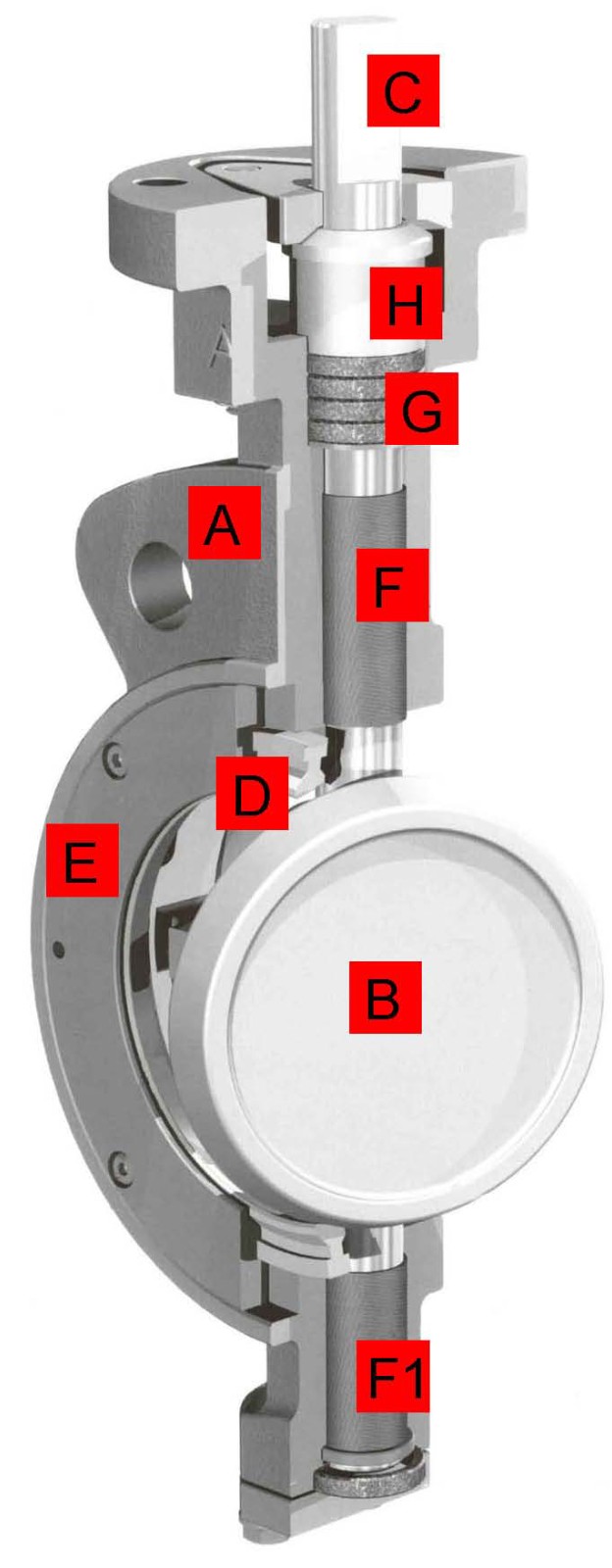

| A BODY: Heavy duty body, double offset type. | | B DISC: Soild stainless steel. | C STEM: one-piece stem with a blowout prevention ring located bottom, The high-strength, one piece stem is 17-4 PH Stainless Steel. The valve stem is standardized for interchangeability of actuators.

| D SEAT: Fully replaceable Energizer encapsulated in RTFE. | E SEAT RETANIER: Retainer is firmly attached by bolts located outside of sealing area, protecting the bolts from corrosion. | F Top bearings: consisting of a 316 Stainless Steel shell with a TFE/glass fabric liner bearing surface securely support the stem. The stem bearings provide excellent resistance to corrosion and distortion from high temperatures and mechanical loading forces. | F 1 Bottom bearings. | G Packing: The stem packing system features easy access to adjusting hex head nuts without requiring removal of the actuator. The system consists of a gland ring, a gland retainer, studs, hex head nuts and lock washers. | H Packing Gland: stainelss steel.

|

|