|

|

Metal Seated or Rubber Seated

|

|

Size Range 1/2" - 64" (15 - 1600mm) Temperature Range

-4°F to 266°F (-10°C to 130°C) Rubber Seat

-4°F to 446°F (-10°C to 230°C) Metal Seat Pressure Ratings

Max. ASME Class 150 (20 bar)

Design Standard BS, EN, AWWA C509, AWWA C515 End Type

Flanged

| |

|

Features and Benefits

Cast Iron Gate Valve, also called Water Gate Valve.It is specially designed to suit for transportation,distribution and extraction system in water, air, oil and gas industry.Their bodies are made from ductile iron or cast iron and have integral flanges which are available in two basic types: non-rising stem (NRS) Inside Screw and rising stem Outside Screw and Yoke type. The inside screw type has the stem actuating thread within the pressure envelope and is non-rising. This type of valve is usually used for non corrosive and reasonably clean services and has a smaller overall height than the outside screw type. The outside screw, rising stem type has the stem actuating thread outside the pressure envelope and can be used on more active media where the fluid might otherwise have an adverse affect on the thread.

|

|

|

|

|

| Non-rising Stem Gate Valve (NRS)

|

|

| Rising Stem Gate Valve |

Design

Resilient seat and Metal Seat are 2 type of seats for Cast Iron gate valve. Before the resilient seated gate valve was introduced to the market, gate valves with a metal seated wedge were widely used. The conical wedge design and angular sealing devices of a metal seated wedge require a depression in the valve bottom to ensure a tight closure. Herewith, sand and pebbles are embedded in the bore. The pipe system will never be completely free from impurities regardless of how thoroughly the pipe is flushed upon installation or repair. Thus any metal wedge will eventually lose its ability to be drop-tight.

A resilient seated gate valve has a plain valve bottom allowing free passage for sand and pebbles in the valve. If impurities pass as the valve closes, the rubber surface will close around the impurities while the valve is closed. A high-quality rubber compound is soft enough to absorb impurities, yet strong enough to wash the impurities through when the valve is opened again. This means that the rubber surface will regain its original shape securing a drop-tight sealing.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Metal Seated Gate Valve |

|

| Resilient Seated Gate Valve (RSGV)

|

|

|

|

|

|

Shield TM Gate Valves are used when the need exists for a device that allows an interruption or cut off in the flow or fluid. Gate Valves arenot to be used for flow modulations as the high velocity through a partially open valve may result in erosive damage to the wedge andseats. Under normal operating conditions, the valve should remain either fully open or fully closed. Installation of a Gate Valve does not depend on the flow direction.

|

|

|

|

|

|

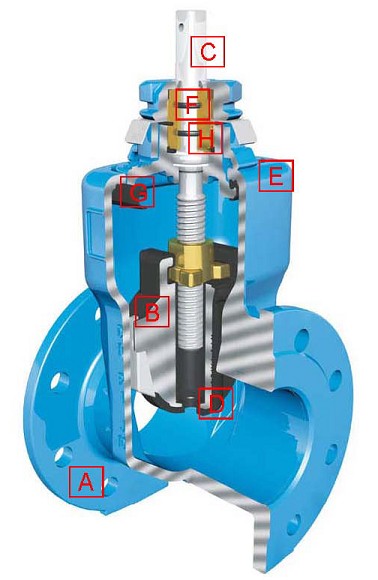

| A BODY: no groove design, prevent from impurities, ensure effective sealing, with Epoxy coating inside, conform to potable water inquirement. |

| B WEDGE: metal frame with rubber lined, ensure rubber sealing and conform to potable water requirement.

|

| C STEM: made of high strength material, ensure gate valve easily controlled. |

| D SEAT: brass seat ensures a reliable positive shut-off in either flowing direction, bubble-tight sealing with low operating torque.

|

| E BONNET: Epoxy coating inside ,conform to potable water requirement. Lifting the wedge fully, the upper design allows sealing O-ring rubber online replaced. |

| F Sealing RING: made of metal frame and several rubber o-rings, to prevent the stem end from leakage. |

| G Wearing washer: to prevent the stem from wearing, ensure the right position and reducing the operating torque. |

| H O-ring, ensures stem ends from leakage.

|

|

|

| |

|

|

|

|

| |

| Size range | Body Material | | 2"~64"(DN50~DN1600) | Ductile iron or Gray iron etc. |

| Temperature range | Stem Material | Rubber seat: -10℃~130℃ Metal seat: -10℃~230℃ | Stainless Steel |

| Pressure ratings | Wedge Material | | Up to ASME Class 150Lb (PN20) | Ductile iron+EPDM |

| Shuttoff ratings | Seat Material | | Bidirectional Bubble-tight | EPDM, Bronze etc. |

| Design and Manufacturing Standard | Face to Face | | MSS SP-70, BS5150, BS5163,EN1171,DIN3352, AWWA C509, AWWA C515, JIS B2031 | ASME B16.10,BS5150, EN558, DIN3202 F4/F5, AWWA C509,JISB2002 |

| End connection | Testing | | Flange: ASME B16.5, EN1092 | MSS SP-61, API 598, EN 12266-1, JISB2003 |

Contact one of Shield's valve and automation experts today to learn more about our Resilient Wedge Gate Valve series.

|

|

|

|

|