|

|

| Metal or Non-metal Seated |

|

Size Range

2" - 60" (50 - 1500mm) Temperature Range

Metal seat: -321°F to 1100°F (-196°C to 593°C)

Soft seat: -10℃~150℃ Pressure Ratings

Max. ASME Class 2500 Port Type Standard port End Type

Flanged, Butt Weld, Wafer, Lugged

| |

|

Design

ShieldTM Check valves are "automatic" valves that open with forward flow and close with reverse flow. The pressure of the fluid passing through a system opens the valve, while any reversal of flow will close the valve. Exact operation will vary depending on the type of Check valve mechanism. Most common types of Check valves are swing, lift (piston and ball), butterfly, stop and tilting-disk. Check valves are ideal for nearly all types of fluid processes with their high sealing performance in both vertical and horizontal piping and their rapid open-close mechanism.

|

|

|

|

|

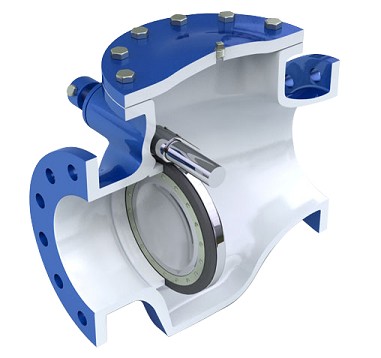

|  | | Plate Check Valve

|

|

| Swing Check Valve |

|

| Tilting Disc Check Valve |

Features and Benefits

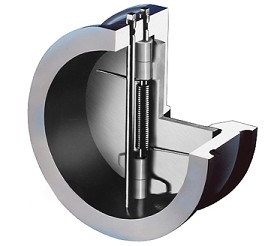

ShieldTM Disc check valves are opened by the pressure of the fluid and closed by the spring as soon as the flow ceases and before the reverse flow occurs.

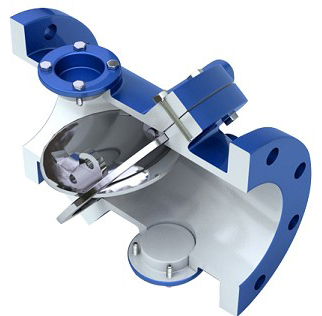

Swing check valve or tilting disc check valve is a check valve in which the disc, the movable part to block the flow, swings on a hinge or trunnion, either onto the seat to block reverse flow or off the seat to allow forward flow. The seat opening cross-section may be perpendicular to the centerline between the two ports or at an angle. Swing Check valves prevent reversal of flow through pipe lines. Most swing check valves can be installed in horizontal or vertical, upward flow, piping. They offer low resistance to flow and are particularly suited to low velocity service.

Tilting Disc Check valves are similar to swing check valves. In most installations, slamming is minimized upon reversal of flow so noise and vibration are reduced.

|

|

|

| |

|  |

|  |

|

|

|

|

|

|

|

|

|

|

|

|

| | Dual Plate Check Valve |

|

| Single Plate check valve |

|

| Metal Body Check Valve |

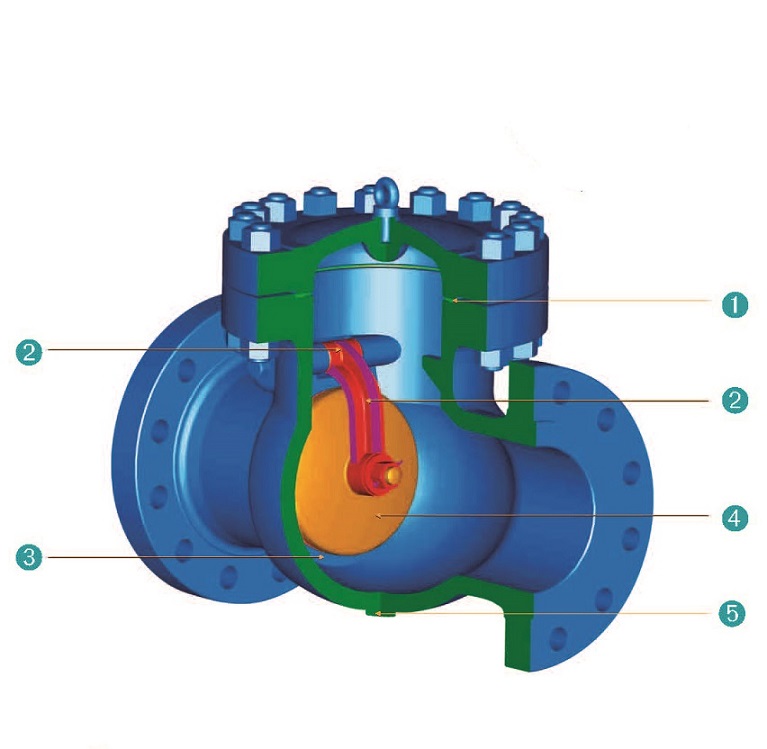

| Swing Check Valve |

| Titling Disc Check Valve | Ductile Iron body with rubber lined |

|

| Rubber or metal seat |

|

| Rubber, PTFE or metal seat |

| Metal seat |

| Rubbe or metal seat

|

|

|

|

|

| 1. Flexible graphite gasket for Class 150 valves, spiral wound gasket for Class 300 & 600 valves, and ring joint for Class 900 & above valves or as an option for the Class 600 valves on customer request. | 2. A hinge and hinge pin provided and mounted so as to permit full movement of the disc.

| 3. Standard renewable seal welded seat with stellite 6 while optional screwed-in seat.

| 4. Standard swing disc type, used in horizontal position for liquid service application or used in vertical position where liquid flow from bottom to top. | 5. Provision of standard bosses for a drain tapping at location G at the lower part of body centerline. Additional bosses conform to customer requirements.

|

|

|

| |

|

|

|

|

| |

| Size range | Body Material | | 2"~12"(DN50~DN300) | Csat Steel, and Alloy Steel etc. |

| Temperature range | Stem Material | | -321°F to 1100°F (-196°C to 593°C) | Forged Stainless Steel |

| Shuttoff ratings | Seat Material | | Undirectional Bubble-tight | As per API600/602 |

| Design and Manufacturing | Face to Face | | API 594, API 6D, ASME B16.34, EN12334, BS3356, BS1868, JIS B2074 | API 594, ASME B16.10, EN558, JIS B2002 |

| End connection | Testing | Flange: ASME B16.5/B16.47, EN1092; JIS B2212 Butt Weld: ASME B16.25, EN12627 | MSS SP-61, API 598, EN 12266-1; JIS B2003 |

| Fire Safety | Nace | | API 6FA, API 607 | NACE MR-0175, NACE MR-0103, ISO 15848 |

Contact one of Shield's valve and automation experts today to learn more about our Swing Check Valve series.

|

|

|

|

|