| Metal Seated |

|

Size Range

2" - 12" (50 - 300mm) Temperature Range

-321°F to 1100°F (-196°C to 593°C)

Pressure Ratings

Max. ASME Class 2500 Port Type Full port, Standard port End Type

Flanged, Butt Welded

Design | |

|

ShieldTM Globe Valve, Generally, has three Patterns with different applications.

TEE PATTERN GLOBE VALVE DESIGN is the most common body type, with a Z-shaped diaphragm. The horizontal setting of the seat allows the stem and disk to travel perpendicular to the horizontal line. This design has the lowest coefficient of flow and higher pressure drop. They are used in severe throttling services, such as inbypass lines around a control valve. Tee-pattern Globe valves may also be used in applications where pressure drop is not a concern and throttling is required.

WYE PATTERN GLOBE VALVES DESIGN is an alternative for the high pressure drop, inherent in globe valves. seat and stem are angled at approximately 45 degrees, what gives a straighter flowpath at full opening and offer the least resistance to flow. They can be cracked open for long periods without severe erosion. They are extensively used for throttling during seasonal or startup operations. They can be rod through to remove debris when used in drain lines that are normally closed.

ANGLE PATTERN DESIGN is a modification of the basic Tee Pattern Globe valve. In applications that have periods of pulsating flow because of their capability to handle the slugging. The ends of this Globe valve are at an angle of 90 degrees, and fluid flow occurs with a single 90 degrees turn. They have a slightly lower coefficient of flow than wye-pattern Globe valves.

|

|

|

|

|

|  | | T Pattern Globe Valve

|

|

| Y Pattern Globe Valve |

|

| Angle Globe Valve |

Features and Benefits

ShieldTM A Globe valves is a linear motion valve and are primarily designed to stop, start and regulate flow. The disk of a Globe valve can be totally removed from the flowpath or it can completely close the flowpath. Conventional Globe valves may be used for isolation and throttling services. Although these valves exhibit slightly higher pressure drops than straight=through valves (e.g., gate, plug, ball, etc.), they may be used where the pressure drop through the valve is not a controlling factor. Globe valves are extensively employed to control flow. The range of flow control, pressure drop, and duty must be considered in the design of the valve to avert premature failure and to assure satisfactory service. Valves subjected to high-differential pressure-throttling service require specially designed valve trim. Versatile, easy to maintain and appropriate for extreme temperatures and pressures, globe valves are among the most popular valves in the petrochemical industry. Globe Valves offer general throttling capabilities as well as on/off properties when fully opened or closed. Casting Steel material; Outside screw and Yoke; Rising Stem; Regular Port; Bolted, and pressure seal bonnet joint; Integral backseat; Metal seated; Extended stem globe valve servers for cryogenic condition; Butt weld and flanged end available;

|

|

|

|

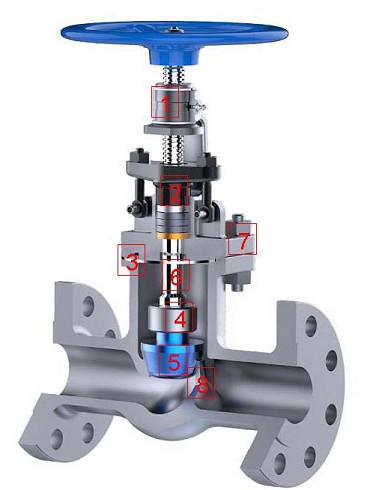

| 1. Stem Nut: Long thread stem nut prolongs thread life and permits the removal of hand wheel in the fully open position. | 2. Spacer ring: Spacer ring in conjunction with packing is used in gate valves of 300 class and above while 150-class valves in only fitted with packing.

| 3. Gasket: Flexible graphite gasket used for 150 Class gate valve, spiral wound gasket for Class 300 & 600 valves and metal ring gasket for gate valves of 900 or greater Class.

| 4. Guide: integral guide inside body keeps wedge self-centered during valve opening and closing. | 5. Disc: one piece flexible disc provides accurate alignment of mating seating surfaces so the valve can absorb piping strains without leakage. Also, it avoids any tendency to stick in the seated position. | 6. Stem: The tee-head disc-stem connection prevents lateral strain on the stem for smooth, easy operation. Accurately cut threads engage the yoke sleeve for positive control of disc position. | 7. Integral Bonnet/ Yoke : All bonnet assemblies are cast and finished to the same exacting tolerances as the bodies for accurate alignment of stems and ease of sealing. | 8. SEAT: Renewable seal welded seats with stellite 6 are standard design while screwed-in seats are optional. |

|