Metal Seated

|

|

Size Range 1/4" - 2" (8 - 50mm) Temperature Range

-321°F to 1100°F (-196°C to 593°C)

Pressure Ratings

Max. ASME Class 4500

Port Type Full port, Standard port End Type

Socket Welded, Threaded, Flanged, Butt Welded

| |

|

Forged Steel Gate Valve

Our Forged Steel Gate Valves are designed to provide reliable and leak-free performance, even under high-pressure and high-temperature conditions. They are made from high-quality materials, such as stainless steel, and are built to last.

Our Forged Gate Valves come in a range of sizes and dimensions to suit your needs, and our catalog includes flanged Forged Gate Valves, API 602 Forged Gate Valves, and more. Our Forged Gate Valves are also available in different classes, including Class 800, Class 1500, and Class 2500, so you can choose the one that suits your specific requirements.

At our Forged Gate Valve manufacturing facility, we have a team of experts who ensure that every valve we produce meets the highest quality standards. Our valves undergo rigorous testing to ensure they meet the required specifications and are ready to perform under even the harshest conditions.

Our Forged Gate Valve weight and pressure ratings are provided in our product specifications, which are available on request. We also offer competitive Forged Gate Valve prices, making it easy for you to get the best value for your money.

In summary, if you need a high-quality, reliable, and long-lasting Forged Gate Valve for your industrial applications, look no further than our Forged Steel Gate Valve. As a leading Forged Gate Valve manufacturer, supplier and exporter, we are confident that our products will exceed your expectations and provide you with the performance and durability you need.

Design

ShieldTM Forge valves are available in THREE bonnet designs. Bolted Bonnet whose bonnet and body are connected by bolt, with male-female joint, spiral wound gasket, made in F316L/graphite. Ring joint gasket are also available on request. Welded bonnet which with the body and bonnet all welded and sealed with a threaded and seal welded joint. On request a full penetration strength welded joint is available. Pressure seal bonnet which the body and bonnet are connected by thread and is self-sealed by inner pressure sealing ring. The higher the inter pressure is, the better the sealing performance is.

|

|

|

|

|

|  | | Bolted Bonnet

|

|

| Welded Bonnet |

|

| Pressure Seal Bonnet |

Features and Benefits

ShieldTM Gate valves are used when there is a need of a device that allows or interrupts a fluid flow. These valves aren’t designed to regulate the flow or its the high velocity. A valve that is partially open can end up damaging the disc or seats. Under normal operating conditions, it must be used totally open or closed. For their design, this type of valves can be used in any position.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|  | |

|

|

|  | | Stem Extended Gate Valve |

|

|

|

| Bellowed Gate Valve |

|

|

|

| Body Extended Gate Valve |

Forged Steel material; Outside screw and Yoke; Rising Stem; Regular Port and full port ; Bolted, welded bonnet and pressure seal bonnet joint; Solid wedge; Integral backseat; Metal seated; Extended stem gate valve servers for cryogenic condition; Threaded end, socket weld end, butt weld and flanged end available; Bellow sealed for bellowed gate valve; Integral body extended available.

|

|

|

|

|

|

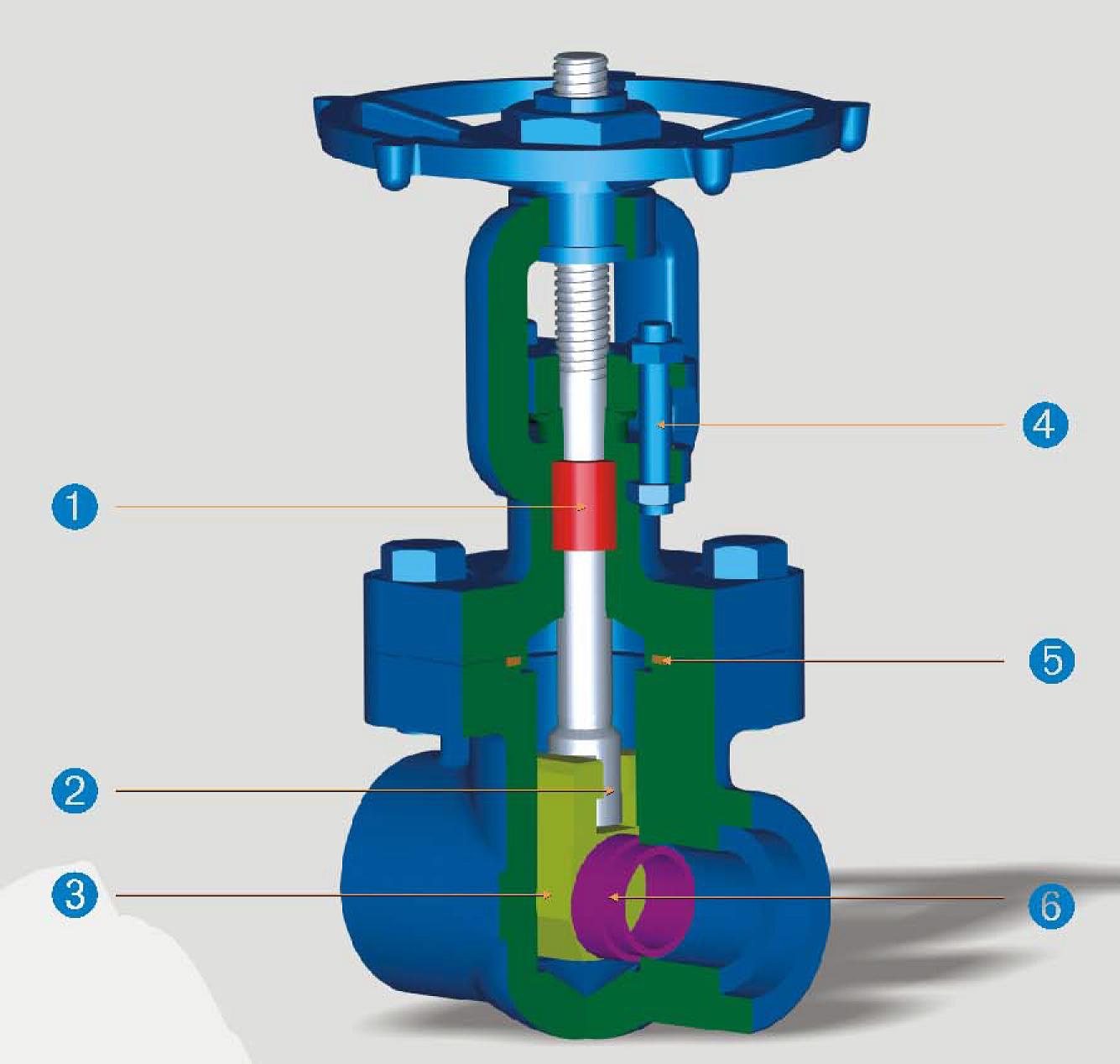

| 1. Back Seat: high quality packing material and improved stuffing |

| box design ensure tight stem seal.

|

| 2. STEM: the T-head stem design provides postive disc to stem |

| connection and ensures effective seating operation. |

| 3. WEDGE: full guided solid wedge reduces wear on seating surface. |

| 4. STUD AND BOLT: arrangement facilitaces packing maintance. |

| 5. BODY/BONNET SEAL: Repossesed body-bonnet joint design |

| captures the stainless steel spiral wound gasket ensuring the sealing integrity. |

| 6. SEAT: Rolled-in seat design ensures tight and effective seat assembly. |

|