|

|

Metal Seated

|

|

Size Range 2" - 60" (50 - 1500mm) Temperature Range

-321°F to 1100°F (-196°C to 593°C)

Pressure Ratings

Max. ASME Class 2500 Port Type Full port, Standard port End Type

Flanged, Butt Welded

| |

|

Design

ShieldTM Gate valves serve as efficient on-off valves with flow in either direction. In such a design, a wedge slides cross a general passageway in order to control fluid flow (like a sliding gate - hence, the name). One of the most significant characteristics of this type of valves is its straight-through, unobstructed passageway when set in the “full open” position. This is made possible by the wedge lifting entirely out of the passageway. As a result, gate valves are characterized by a minimum of turbulence and pressure drop in operation.

While gate valves are good for applications requiring these two factors, they are not recommended for installations in which throttling would be a function. They are designed for on/off service.

|

|

|

|

|  | | Bolted Bonnet

|

|

|

|

| Pressure Seal Bonnet |

Features and Benefits

ShieldTM Gate valves are primarily designed to start or stop flow, and when a straight-line flow of fluid and minimum flow restriction are needed. In service, these valves generally are either fully open or fully closed. The disk of a Gate valve is completely removed when the valve is fully open; the disk is fully drawn up into the valve Bonnet. This leaves an opening for flow through the valve at the same inside diameter as the pipesystem in which the valve is installed. A Gate valve can be used for a wide range of liquids and provides a tight seal when closed. There are three different disks or wedges available for Gate valves, solid wedge, flexible and split wedge. Ranging of the Gate valves is usually made by the type of wedge used.

Casting Steel material; Outside screw and Yoke; Rising Stem; Regular Port and full port ; Bolted, and pressure seal bonnet joint; Solid wedge, flexible wedge, split wedge; Integral backseat; Metal seated; Extended stem gate valve servers for cryogenic condition; Butt weld and flanged end available; Integral body extended available.

|

|

|

|

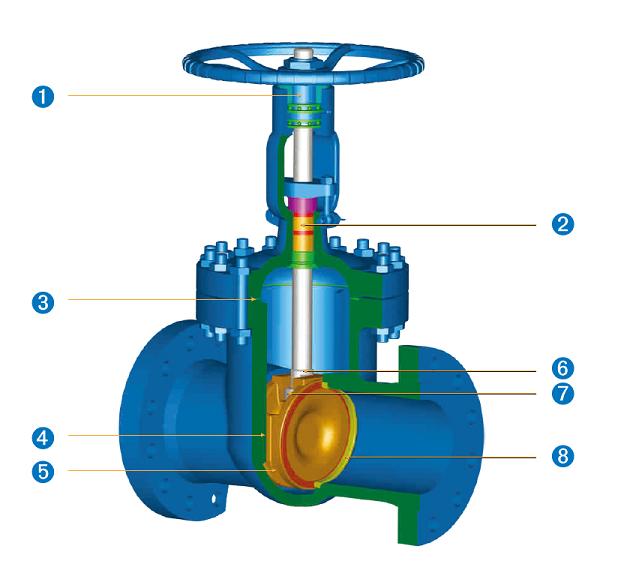

| 1. Stem Nut: Long thread stem nut prolongs thread life and permits the removal of hand wheel in the fully open position. | 2. Spacer ring: Spacer ring in conjunction with packing is used in gate valves of 300 class and above while 150-class valves in only fitted with packing.

| 3. Gasket: Flexible graphite gasket used for 150 Class gate valve, spiral wound gasket for Class 300 & 600 valves and metal ring gasket for gate valves of 900 or greater Class.

| 4. Guide: integral guide inside body keeps wedge self-centered during valve opening and closing. | 5. Wedge: Flexible wedge is able to compensate for seat surface distortion and body deformation caused by piping stress. | 6. Stem: Blowout retention design: the tapered backseat face firmly contacts backseat of bonnet. | 7. Bonnet/ wedge : The strength of bonnet-wedge connection exceeds that of bonnet thread root. | 8. SEAT: Renewable seal welded seats with stellite 6 are standard design while screwed-in seats are optional. |

|

|

| |

|

|

|

|

| |

| Size range |

|

|

| Body Material | 2"~50"(DN50~DN1500) |

|

|

| Csat Steel, and Alloy Steel etc. |

| Temperature range |

|

|

| Stem Material | -321°F to 1100°F (-196°C to 593°C) |

|

|

| Forged Stainless Steel |

| Pressure ratings |

|

|

| Wedge/Trim Material | Up to ASME Class 2500Lb

|

|

|

| As per API600/602 |

| Shuttoff ratings |

|

|

| Seat Material | Bidirectional Bubble-tight |

|

|

| As per API600/602 |

| Design and Manufacturing Standard |

|

|

| Face to Face | API 602, API600, API6D, ASME B16.34, EN3352, BS5352 |

|

|

| API 6D, ASME B16.10, EN558, ISO 5752, BS2080 |

| End connection |

|

|

| Testing | Flange: ASME B16.5/B16.47, EN1092 Butt Weld: ASME B16.25, EN12627 |

|

|

| MSS SP-61, API 598, EN 12266-1 |

| Fire Safety |

|

|

| Nace | API 6FA, API 607 |

|

|

| NACE MR-0175, NACE MR-0103, ISO 15848 |

Contact one of Shield's valve and automation experts today to learn more about our Cast Steel Gate Valve series. |

|

|

|

|