| Metal Seated & Resilient Seat |

|

Size Range

2" - 12" (50 - 300mm) Temperature Range -4°F to 446°F (-10°C to 230°C) Pressure Ratings Max. ASME Class 150 (20 bar) Design Standard BS, EN, JIS End Type Flanged

| |

|

Features and Benefits

Cast Iron Globe Valve, also called water globe valve.It is specially designed to suit for transportation,distribution and extraction system in water, air, oil and gas industry.Their bodies are made from ductile iron or cast iron and have integral flanges which are available in two basic types;non-rising stem Inside Screw and rising stem Outside Screw and Yoke type. The inside screw type has the stem actuating thread within the pressure envelope and is non-rising. This type of valve is usually used for non corrosive and reasonably clean services and has a smaller overall height than the outside screw type. The outside screw, rising stem type has the stem actuating thread outside the pressure envelope and can be used on more active media where the fluid might otherwise have an adverse affect on the thread.

|

|  |

|

| | Angle Globe Valve

|

| BS Globe Valve |

| DIN Globe Valve |

Design

Globe valves are mainly used to regulate or adjust the fluid’s volume. Globe valves are not recommended for great quantities of fluid because high pressure will go down because of the valve’s design. This type of valve must be always installed in a way that the fluid goes in through the base of the seat of the valve. These valves have and arrow in their body to indicate the direction in which the fluid must go. These valves will be used with fluids that contain particles in suspension. • Globe Valve-Flanged Ends

• 200 WOG - 125 SWP • Cast Iron Body • Bituminous Coating • Bolted Bonnet • Outside Screw & Yoke Rising Stem • Cast Bronze Disc & Seat • Conical disc, one piece designed with guides for the disc for performance under any service circumstance, mainly, for sever turbulence conditions and vibrations in the rod • Service conditions for water, oil, air, gas, vapor, and pump systems

|

|

|

|

|

|

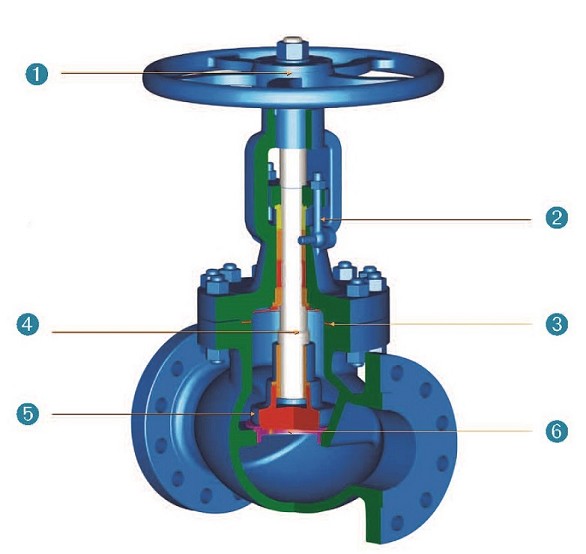

| 1 Impact handwheel supplied at manufacturer's option or on customer request. |

| 2 Gland eyebolts are mounted to swing aside to facilitate packing maintenance.

|

| 3 Male and female bonnet joints for Class 150 valves. |

| 4 Anti blow-out stem design with conical backseat surface to permit repacking of valve in the fully open position.

|

| 5 Plug seat surface is standard disc design as well as spherical, parabola or flat seating surface is optional on customer request. |

| 6 Seat face with Brass is standard design. |

|