|

|

| Metal Seated |

| Size Range

1/4" - 2" (8 - 50mm) Temperature Range

-321°F to 1100°F (-196°C to 593°C)

Pressure Ratings

Max. ASME Class 4500

Port Type Full port, Standard port End Type

Socket Welded, Threaded, Flanged, Butt Welded

| |

|

Design

ShieldTM Forged Steel Check valves are compact, sturdy and ideal for high pressure and high temperature applications. The Forged Steel check valves are available in three bonnet designs.

Bolted Bonnet whose bonnet and body are connected by bolt, with male-female joint, spiral wound gasket, made in F316L/graphite. Ring joint gasket are also available on request. Welded bonnet which with the body and bonnet all welded and sealed with a threaded and seal welded joint. On request a full penetration strength welded joint is available. Pressure seal bonnet. These valves shall be bolted bonnet or welded bonnet type with full or standard bore options.

|

|

|

|

|

|

|

|

| | Bolted Bonnet |

|

|

| Welded Bonnet |

|

|

| Pressure Seal Bonnet |

Features and Benefits

The forged steel check valves are also available in three different design configurations. These are forged piston check valve, also called lift check valve (spring loaded check valve ), forged ball check valve and forged swing check valve. Forged cryogenic check valves which serves for temperatures down to -321°F (-196°C) are available as well.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|  | |

|

|

|  | | Lift Check Valve |

|

|

|

| Swing Check Valve |

|

|

|

| Ball CheckValve |

Piston check valve, like all check valves, are used to prevent back flow in the line. As an option the designs can include a spring to assist closing and for use in 90-degree styles installed in vertical lines. The pressure of the fluid passing through a system opens the valve, while any reversal of flow will close the valve. In Piston, or lift, check valves a body-guided disc moves within the body bore. The body guide ensures alignment of the seat and dics when the valve closes.

Swing check valves, like all check valves, are used to prevent back flow in the line. The pressure of the fluid passing through a system opens the valve, while any reversal of flow will close the valve. The swing check valve functions by allowing flow forces to move the closure element, it is a hinged clapper which swings or rotates around a supporting shaft. The disk swings away from the valve-seat to allow flow in the forward direction, and returns to the valve-seat when upstream flow is stopped, to prevent backflow.

The function of ball check valves is similar to the piston check, but the ball check valves use a “ball” inside the body to control the movement of flow. The ball is free to rotate, resulting in even wear and a wiping action between the ball and seat. This feature makes ball checks useful for viscous media.

|

|

|

|

|

|

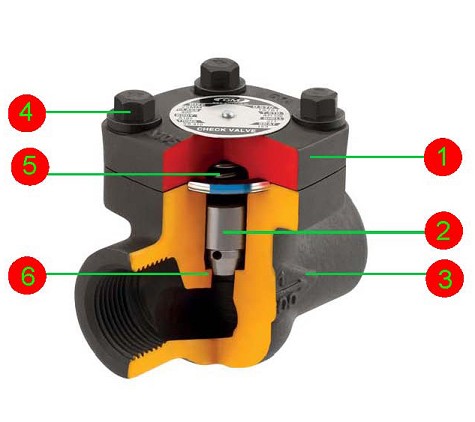

| 1. BODY |

| Forged steel and is available in both the full or standard port design. It is also available in either T-Pattern or Y-Pattern configurations.

|

| 2. PISTON, BALL OR DISC |

| The piston, ball or disc is forged steel and is part of the valve trim. The seating surface of the piston and ball check is of the tapered or plug type design. The seating surface of the swing check is of the flat seat design. |

| 3. Cover The cover is forged steel and designed to the basic dimensional requirements of the applicable specifications. |

| 4. COVER BOLTING The cover bolting is manufactured of alloy steel in accordance with the requirements of the applicable specifications. |

| 5. SPRING |

| The spring is optional and supplied only upon request. |

| 6. SEAT

The body seat for the piston and ball check valves is an integral weld overlay and is part of the valve trim. The swing check valve is supplied with a separate seat ring which is pressed into the valve body and wedged into place, forming a seal with the body. |

|

|

| |

|

|

|

|

| |

| Size range | Body Material | | 1/4"~2"(DN8~DN50) | Forged Steel, Forged Alloy Steel etc. |

| Temperature range | Spring Material | | 321°F to 1100°F (-196°C to 593°C) | Stainless Steel |

| Pressure ratings | Wedge/Trim Material | | Up to ASME Class 4500Lb | As per API600/602 |

| Shuttoff ratings | Seat Material | | Undirectional Bubble-tight | As per API600/602 |

| Design and Manufacturing | Face to Face | | API 602, ASME B16.34, EN3356, BS5352, JIS B2074 | ASME B16.10, EN558, ISO 5752, JIS B2002 |

| End connection | Testing | Flange: ASME B16.5, EN1092; JIS2212 Butt Weld: ASME B16.25, EN12627 Socket Weld: ASME B16.11, EN12760, Thread: ASME B1.20.1, EN10226 | MSS SP-61, API 598, EN 12266-1 |

| Fire Safety | Nace | | API 6FA, API 607 | NACE MR-0175, NACE MR-0103, ISO 15848 |

Contact one of Shield's valve and automation experts today to learn more about our Forged Steel Check Valve series. |

|

|

|

|