|

|

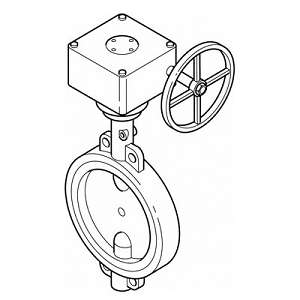

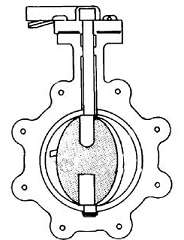

Shield Valves TM Resilient seated butterfly valve, also called Centerline elastic seat soft sealing butterfly valve. Its center of the stem, the center of the disc, and the center of the body is in the same line. The structure is simple and the manufacturing is easy. Because of the disc and the valve seat is always in a state of squeezing and scratching; so the resistance distance is large and the wear would be fast. In order to overcome squeezing and scratching, and to ensure the sealing performance, the valve seat basically uses elastic materials such as rubber or polytetrafluoroethylene; The operating temperature shall be in the range of -20°C to 120°C because of the sealing material limited by temperature. Resilient seat butterfly valve is an excellent choice for continuous adjustment and control, with ultimate pressure to 250 psi and vacuum to 24"Hg.

|

| RUBBER LINED BUTTERFLY VALVE | PTFE LINED BUTTERFLY VALVE |

Application Field

The centerline butterfly valve is a component used to realize the on-off and flow control of the pipeline system. It is designed to handle various liquids and gases, and is suitable for working conditions with low pressure and high sealing performance requirements.

At present, it has been widely used in many fields such as petroleum, chemical industry, metallurgy, hydropower, food and beverage, acid treatment, highly corrosive industry and gas. In the well-known butterfly valve technology, its sealing form mostly adopts a sealing structure, and the sealing material is rubber, polytetrafluoroethylene, etc. Due to the limitation of structural characteristics, it is not suitable for industries such as high temperature resistance, high pressure resistance, corrosion resistance, and wear resistance.

|

|

|

| | Food and sanitary industry | Drinking and waste water | Gas and oil | Corrosion resistance |

Features & Benefits

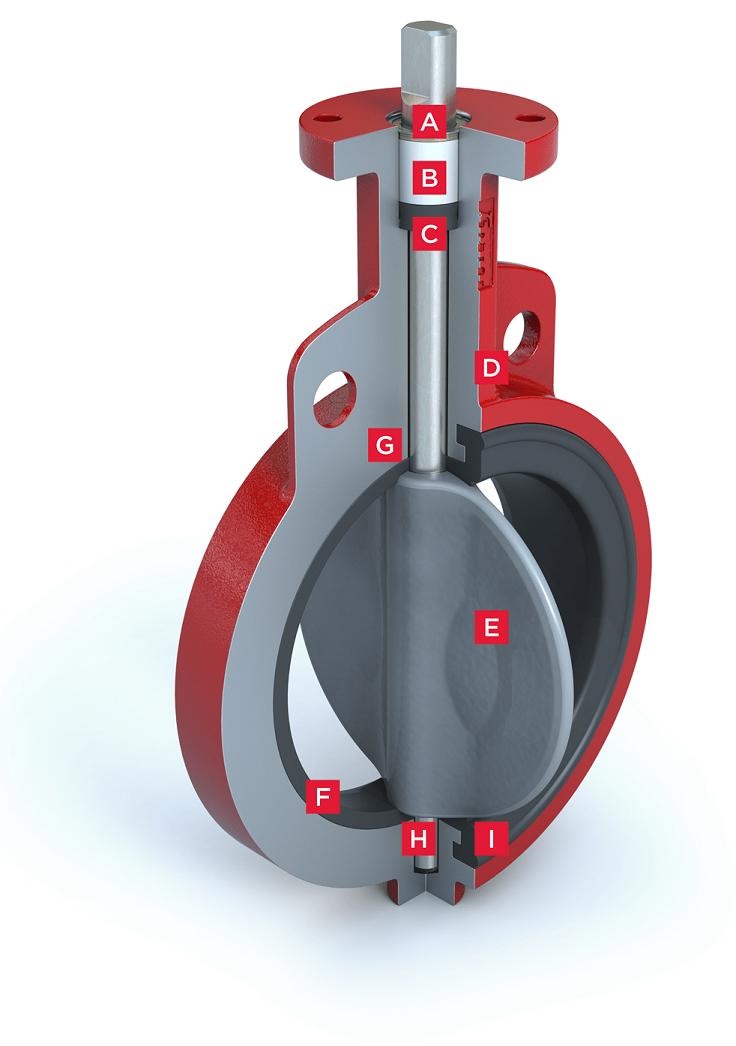

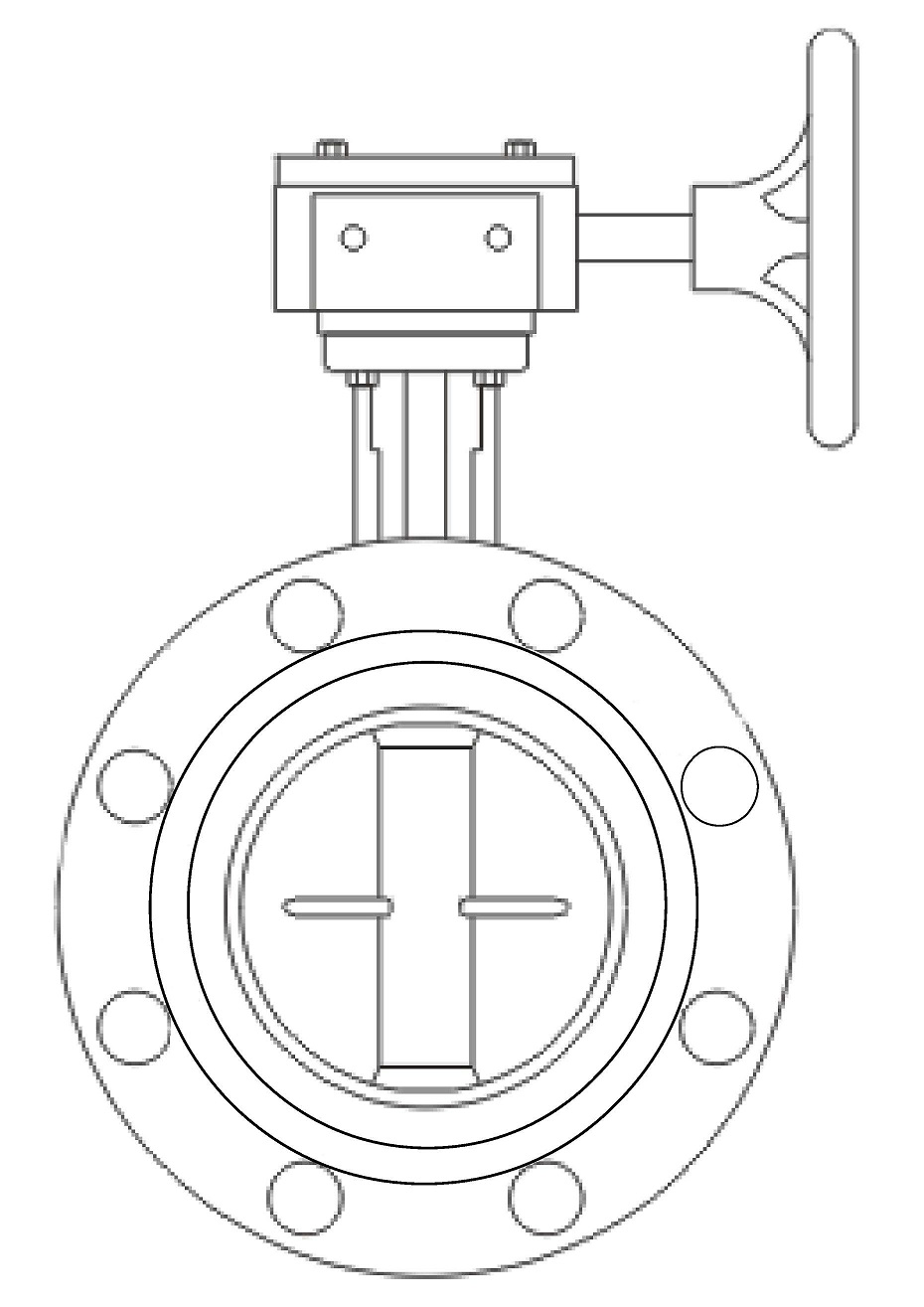

Shield resilient seated butterfly style one-piece or two a valve stem having a straight two-stage design and high strength without the pin, and using the inner valve stem connected to the valve. The main connection methods of the valve are wafer type, lug type and flange type.

Our butterfly valve is designed to provide two-way air-tight closure and isolate the pipeline medium from the valve stem or valve body, with low torque and easy closing. And it has a variety of high-quality elastic seat and disc materials for various applications, which can easily realize the automation of on/off or adjustment services.

| A Gland:material stainless steel. It prevents unintentional removal of the stem during field service. | B Stem Bushing:Non-corrosive, heavy duty acetal bushing absorbs actuator side thrust. | C Stem seal: Self-adjusting and gives positive sealing in both directions. | D Neck:Extended neck length allows for 2" of piping insulation and is easily accessible for mounting actuators. | E Disc:Casting is spherically machined and hand polished to provide a bubble-tight shutoff, minimum torque, and longer seat life. | | F Body: Polyester coating for excellent corrosion resistance. Nylon 11 coating is available as an option. | G Secondary Seal: These seals prevent line media from coming in contact with the stem or body. Primary Seal is achieved by an interference fit of the molded seat flat with the disc hub. Secondary Seal is created because the stem diameter is greater than the diameter of the seat stem hole. | H Stem:The stem drives the valve disc is an exclusive feature of the valve. Disassembly of the stem is just a matter of pulling the stem out of the disc. | I Seat:The seat lowers torque and provides complete isolation of flowing media from the body. The seat also features a molded O-ring which eliminates the use of flange gaskets. |

|

|

|

| | Epoxy coating | Various materials | Low pressure only≤PN16 | Kinds of actuators | | Colorful coating option | CI, DI, WCB, SS, Al-bronze etc. | Flange connection:GB、ASME、EN、JIS etc. | Handle; Gear; Pneumatic and electrical actuator etc. |

ISO TOP FLANGE |

| meet to ISO 5210 standard

|

| Various Connection Ends.

| Be compatible with GB PN16, ASME B16.5/16.47150Lb, JIS10K, EN1092 PN16

|

|

|

| Wafer end

NPS 1 1/2"~24" DN40~DN600 | Lugged end

NPS 1 1/2"~48" DN40~DN1200 | Flanged end

NPS 2"~120" DN50~DN3000 |

|

|

| |

|

|

|

|

| |

| Size range | Body Material | Wafer type: 2"~24"(DN50~DN600) Lug type: 2"~48"(DN50~DN1200) Flange type:2"~12"(DN50~DN3000) | Cast iron, Ductile Iron, Carbon Steel, Al-bronze etc. |

| Temperature range | Stem Material | | -20°F to 400°F (-29°C to 204°C) | Stainless Steel, Monel K500 |

| Pressure ratings | Disc Material | 175 psi (12 Bar) 150 psi (10 Bar) | Nylon 11 Coated Ductile Iron, Aluminum Bronze, Stainless Steel |

| Shuttoff ratings | Seat Material | | Bidirectional Bubble-tight | Bonded EPDM, Bonded BUNA-N, Bonded FKM,PTFE |

| Design and Manufacturing Standard | Face to Face | | API 609, EN593, JISB2032, GB/T12238, AWWAC504 | API 609, EN558, JISB2002, GB/T12221, AWWAC504 |

| End connection | Testing | ASME B16.1 Class 125, ASME B16.5 Class 150, EN 1092 PN10, PN16, GB/T 17241, GB/T 9113, JIS B2220 | MSS SP-61, API 598, EN 12266-1,JIS B2003, GB/T13927 |

Contact one of Shield's valve and automation experts today to learn more about our Resilient Seated Butterfly Valve series. |

|

|

|

|